Differences Between Compressors: Screw vs. Piston – Which One Should You Choose?

When choosing a compressor, one of the most common questions is: screw or piston? Each type serves different purposes, and selecting the right one can help you save both time and money in the long run. Let’s look at the key differences between these two compressor types.

1.Working Principle

- Piston Compressor:

Compresses air through a moving piston inside a cylinder. It’s mechanically simple but creates more noise and vibration. - Screw Compressor:

Uses two rotating screws (rotors) to compress air. It’s more durable, quieter, and energy-efficient.

2.Application Areas

- Piston:

Ideal for short-term and low-duty work. Common in car repair shops and small workshops. - Screw:

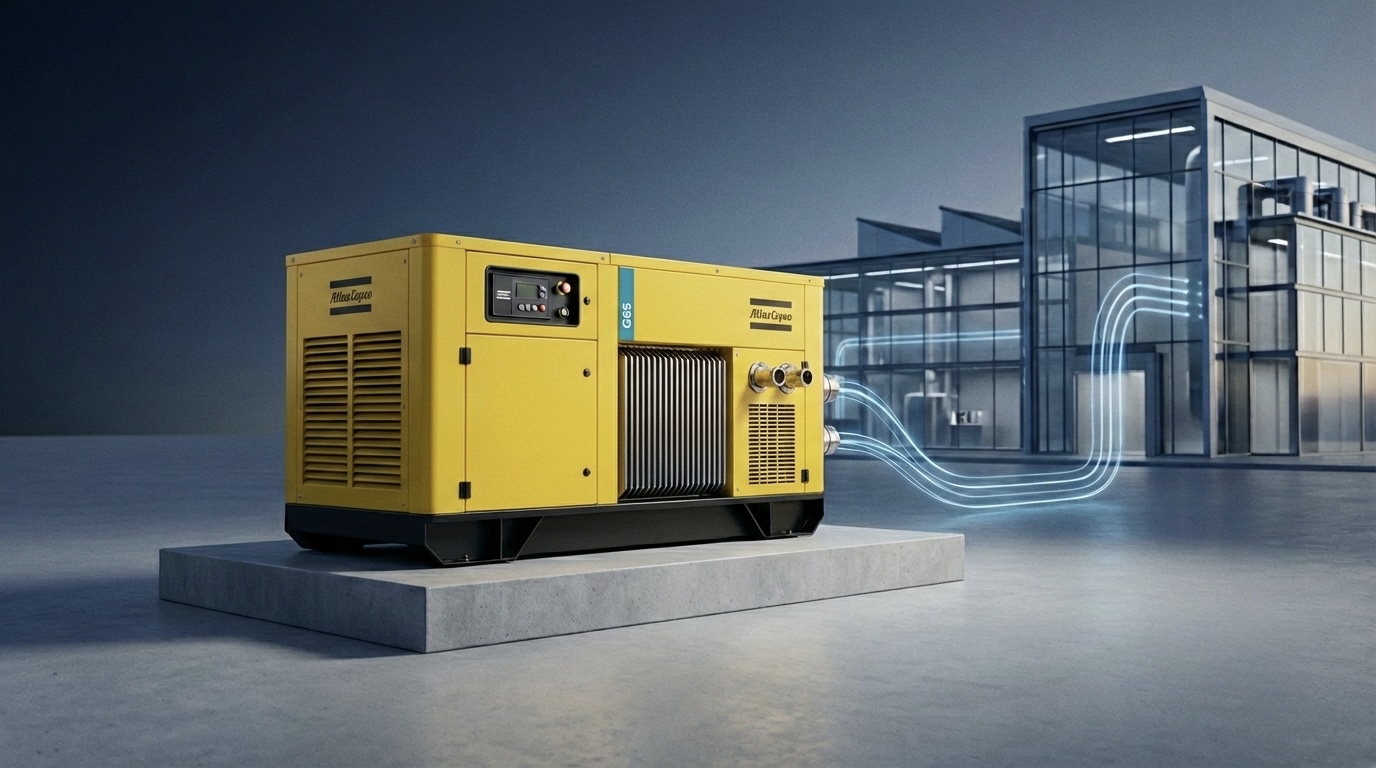

Perfect for continuous, long-term, and high-duty operations. Used in factories, industrial plants, and large-scale projects.

3.Noise & Vibration

- Piston: Noisier and produces more vibration – not ideal for quiet environments.

- Screw: Operates quietly and steadily – suitable even near office zones.

4.Maintenance & Service

- Piston:

Cheaper spare parts and maintenance but requires more frequent servicing. - Screw:

Higher upfront cost but more reliable and needs less frequent maintenance.

5.Price & Efficiency

- Piston:

Lower initial cost, but higher long-term energy and service expenses. - Screw:

More expensive at the start, but efficient and cost-saving over time.

Conclusion: Which One Is Right for You?

- For short-term and light-duty needs → Piston Compressor

- For long-term, heavy-duty industrial use → Screw Compressor

Not sure which is best for your business? Our experts at Atlas are ready to help you make the right choice.

Browse Now:

View our View our compressor catalog catalog

Contact us: +994 51 232 55 55