Losing lighting at a worksite is not just an inconvenience — it means wasted time and additional costs. In construction, infrastructure, and industrial projects, downtime can disrupt project schedules. That’s why choosing the right energy and lighting solution is crucial.

1. Define Your Needs Accurately

Start by assessing the scale of your project and its power requirements. Consider the size of the area to be lit, the energy consumption of your equipment, and working hours. This will help you choose a generator and light tower with the right capacity.

2. Plan the Generator and Light Tower Together

Renting only a generator is not always enough. Especially during night work or in poorly lit environments, light towers are essential. The generator + light tower combination provides both power and lighting simultaneously.

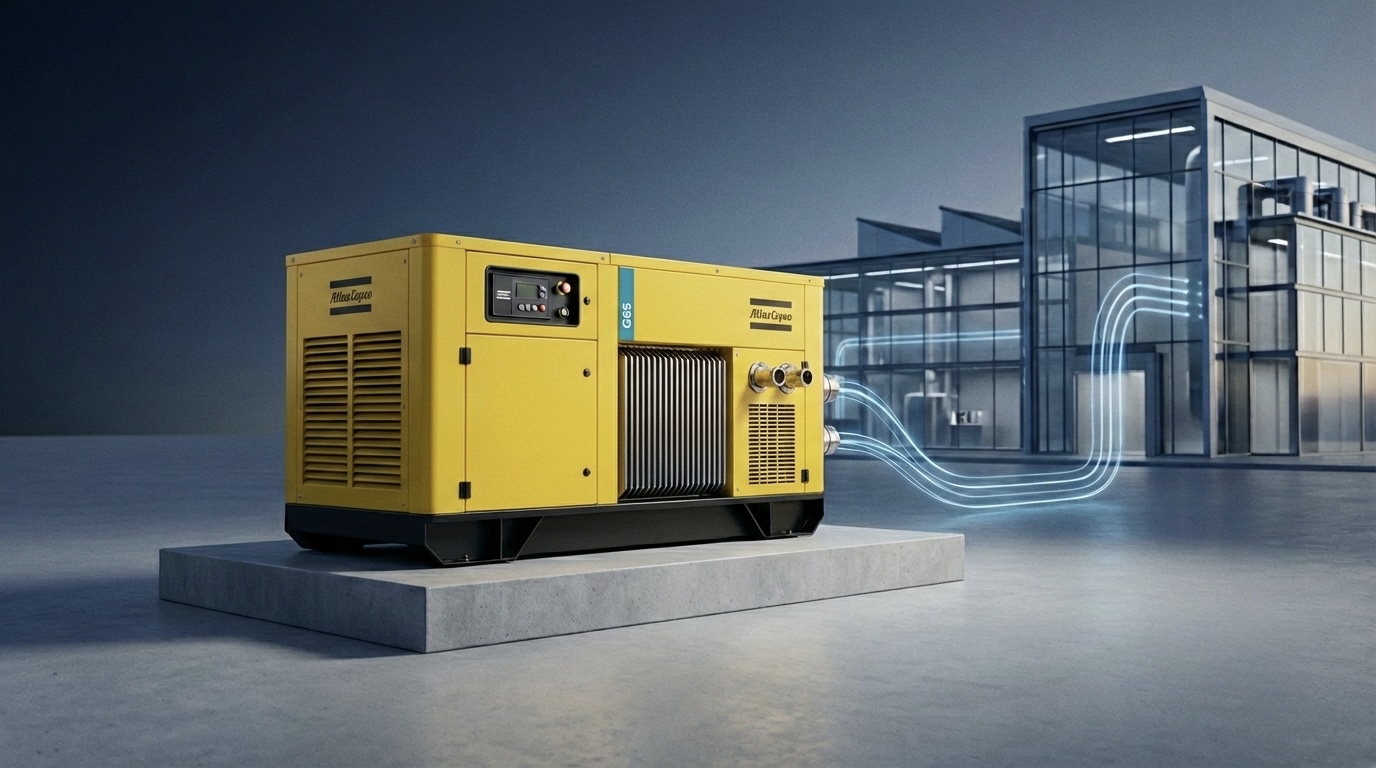

At Atlas, we offer these solutions as a package to ensure zero downtime on site.

3. Have a Backup Plan

Even on the most professional sites, technical malfunctions can occur. That’s why it’s important to have a backup generator and additional lighting sources. Alternative solutions help avoid work interruptions.

4. Conduct Regular Maintenance

The condition of the generator and light tower directly impacts performance. Regularly check oil levels, filters, and cables.

5. Follow Safety Guidelines

When working with power and lighting equipment, safety is paramount. Use protective gear, insulated cables, and proper connection methods to prevent hazards.

Conclusion

Ensuring uninterrupted energy and lighting at a worksite requires proper planning, the right equipment, and professional technical support.

Atlas offers a generator + light tower solution to keep your projects on schedule and running smoothly.